How Supply Chain Disruption Affects Churches

Published on: Tuesday, March 29, 2022 - 7:00am

It’s no secret that the global supply chain is in the midst of a major disruption.

Shortages and delays are affecting nearly every major industry, including construction. Resources like steel, lumber, and labor are all in short supply, extending the timelines of projects and causing rampant delays.

If you’re looking at updating your church building, or if you’re building something entirely new, how will these supply chain issues affect the audio, video, and lighting aspects of your project? Read on to find out how you can look ahead, prepare, and adjust your expectations for what church construction will involve during these times.

What’s Disrupting the Supply Chain?

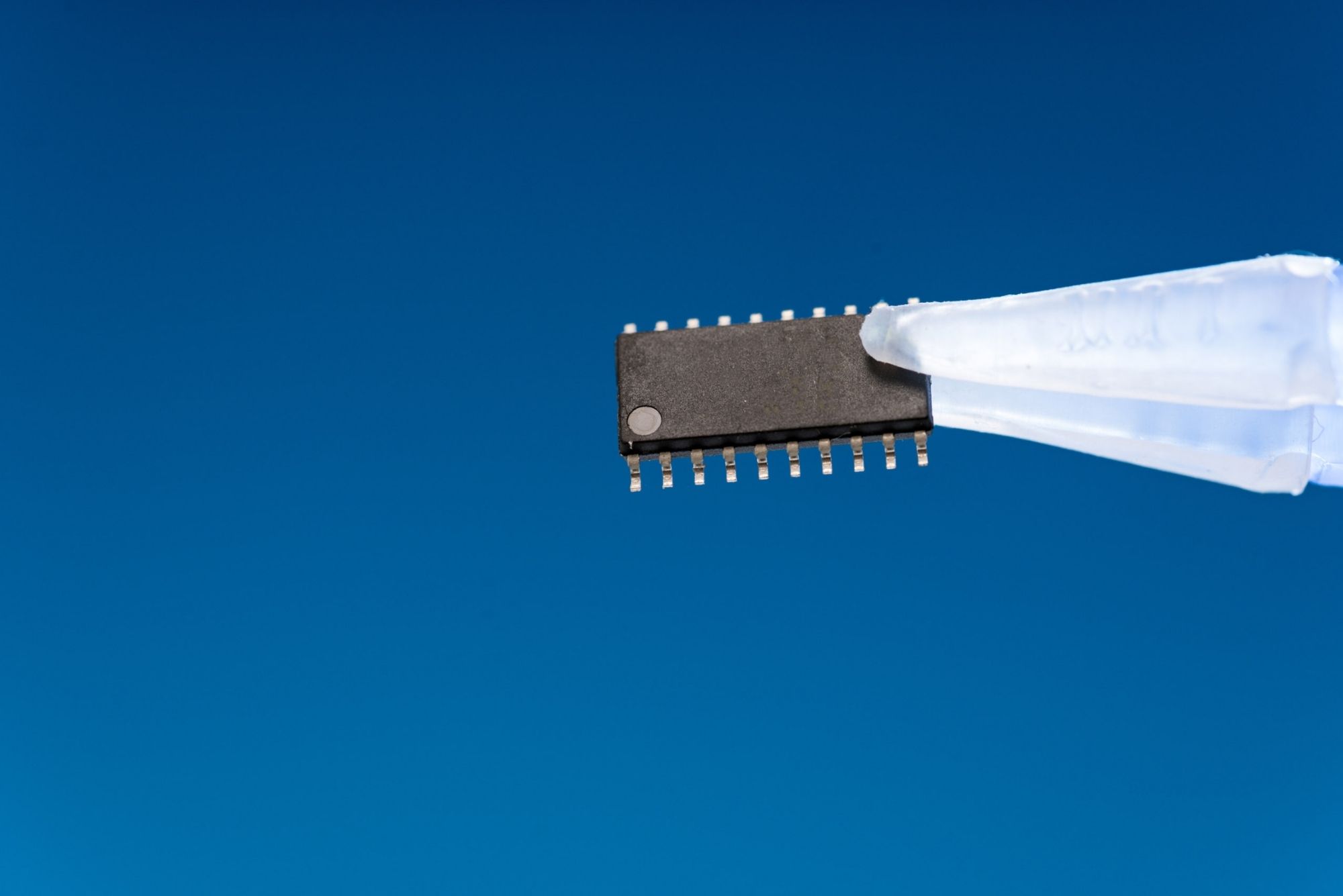

One of the major reasons for our supply chain difficulties today is that demand is far outweighing supply, especially when it comes to semiconductors, or microchips.

Chips are used in just about every electronic device you own, from automobiles to phones to electric toothbrushes. Even before 2020, demand for chips was on the rise and manufacturers were beginning to have trouble keeping up. Early signs of trade sanctions against China led to tech companies stocking up on chips. This put a deeper and immediate strain on the supply of these materials.

And then the pandemic hit.

During quarantine, chip manufacturing plants shut down for months, which meant new chips weren’t being produced while demand for consumer technology exploded. People were working and learning from home, and they needed new laptops, new iPads, new cameras, etc., quickly running through the existing chip supply.

When manufacturing started again, certain key factories were crippled by fire and severe winter weather, further reducing global production capacity. Meanwhile, the backlog continued to increase.

The chip shortage spills into every facet of modern life because of how deeply technology is involved in our world. And AVL equipment is no exception.

How Do Shortages Impact Churches Specifically?

Nearly all AVL equipment uses chips and other components that are in extremely short supply.

In addition to chips, manufacturers are struggling to acquire the raw materials needed to build their equipment. They’re having to prioritize certain product lines and, therefore, pause others indefinitely. Some products are able to ship within weeks, others are on 12-month or longer backorders, and some manufacturers simply will not accept orders for groups of their product lines.

Lead times continue to stretch longer and longer and are very unpredictable.

For churches working on a construction project or AVL renovation, it’s a difficult situation. If this is your case, you can take one of two paths:

- Build your project schedules to allow time to wait for the equipment you prefer and designed into your systems.

- Alter designs and choose equipment that’s attainable within your project timeline.

If keeping to your timeline is essential, then you should consider using technology that’s available on your schedule, even if it’s not what you initially hoped for. On the other hand, if specific technology is important to you and your church, then you might have to accept a protracted timeline.

The Bad News: Timeline and Price

Timelines on equipment are now extremely unpredictable. They change on a weekly, if not daily, basis. Consequently, there’s no way to predict lead times once an order is placed. Even when we hear a lead time from a manufacturer, we can’t assume it will remain safe.

For example, one speaker manufacturer was operating on an 8–10 week lead time in December. In January, just a few weeks later, they let us know their waiting period had extended to 8–12 months.

Another company that had long-but-manageable lead times on digital consoles had to suddenly pause production entirely. This manufacturer informed dealers in November that they would not be accepting orders for certain consoles and hardware for approximately 12 months.

Furthermore, issues in the supply chain, scarcity of labor and work stoppages, and massive inflation in freight costs are causing instability in pricing models. Manufacturers are having to increase prices more often and more quickly than we’ve ever seen in the past.

In pre-pandemic years, manufacturers would typically re-confirm or enact price increases on equipment once per year. Over the past 18 months, we’ve seen prices increase between two and eight times, depending on the manufacturer and equipment.

Previously, quotes for custom or specialized equipment would remain valid for multiple months. With manufacturer costs changing so quickly, quotes can now become invalid in 10 days or less.

The Good News: Churches Can Plan Around the Problem

Despite how it may sound, you can still build or upgrade right now. However, it’s important now more than ever to work with a trusted firm that can help you navigate these incredibly volatile circumstances.

If you’re working with a team you trust that’s committed to bringing you solutions, they’ll be able to help you find available systems and products that are the most efficient for your project.

It’s also essential that churches act quickly. Plan for extended lead times by starting projects early and recognizing that they will require more time than in the past.

Lastly, it always helps to be decisive; make sure you’re not putting off decisions and delaying action. Just as important, be flexible; make room for new solutions when supply chain problems interfere with plans.

How Long Will This Last?

Unfortunately, the chip shortage and other supply chain issues aren’t going away any time soon.

We will feel the impact of these issues until the end of 2023 or possibly 2024. Intel chief Pat Gelsinger predicted that it would be a year or two before chip supply could catch up with demand, but that was in the summer of 2021. More global setbacks have occurred since then.

The bottom line: Waiting it out could take years.

If you’ve been planning on a new build or upgrade, the important question to ask right now is, can you wait that long?

How important is the project? Will waiting interfere with reaching your missional objectives?

If you decide not to wait, our best advice is to get started as soon as possible. The earlier you start your project, the more time and flexibility you’ll have as you move forward.